Foundations from History: The Twin Towers

By Michael Bennett, P.E. (A.G.E.S., Inc., King of Prussia, PA)

Author’s Note: This piece is dedicated to the memory of the victims of the terrorist attacks against the United States on February 26, 1993, and September 11, 2001.

The magnitude of the engineering challenge posed by the proposed World Trade Center complex in New York City became clear as soon as plans for it were unveiled in January of 1964. The plans set forth by the Port of New York Authority (now known as the Port Authority of New York and New Jersey), within whose jurisdiction the site lay, called for several lower-lying office buildings to surround two gargantuan towers, each 1,350 feet (110 stories) high. Yet the selected site on the west side of Lower Manhattan quickly became a concern for the Port Authority engineers tasked with designing the skyscrapers, which were soon dubbed the Twin Towers. Geotechnical borings drilled at the site indicated that it contained layer upon layer of marginal soils, including: 15 to 35 feet of debris-laden fill; 10 to 30 feet of soft organic marine clay mixed with glacial sand and silt; and 5 to 20 feet of glacial till and saprolitic conglomerate. While bedrock at the site consisted of competent Manhattan schist, it lay about 65 to 80 feet below street level. Meanwhile, the groundwater table lay just a few feet below street level. Moreover, two subway tubes for the Port Authority Trans-Hudson (PATH) commuter rail line lay buried within the site. Lastly, since the site was adjacent to the Hudson River, the possibility of a breach during construction had to be considered. With all these challenges in mind, the geotechnical engineers of the Port Authority got to work (Aronowitz 2002, PANYNJ 1983, Tamaro 2002, WTC 2020).

Model of the proposed World Trade Center in Lower Manhattan as revealed in early 1964, with seven-foot-tall renderings of the Twin Towers.

Source: Time (1964).

The Port Authority geotechs soon decided that deep foundations were too risky to use for the Twin Towers because, as one engineer succinctly put it, “the planned buildings were so big and so heavy[.]” Furthermore, the high groundwater table at the site would have required the use of costly solutions such as thick base slabs or vertical tie-down anchors to construct the large subterranean parking garages desired by their counterparts in the Port Authority’s planning group. Instead, the geotechnical design team chose to excavate down to bedrock and place the towers’ foundations directly on Manhattan schist. To do so most economically, the team opted to construct a below-grade cutoff wall around the site and to dewater and excavate the soil within it. The cutoff wall would localize the region of dewatering, which would help maintain the surrounding groundwater table and eliminate the risk of damaging adjacent buildings and utilities due to excessive settlement (Aronowitz 2002, PANYNJ 1983, Ressi 2011).

Martin Kapp, chief geotech for the Port Authority, made the decision to seal off the World Trade Center site using a so-called slurry or diaphragm wall. While the technology had already become popular overseas by the mid-1960s, it had only been used twice in the USA. Accordingly, the Port Authority sent engineer George Tamaro on a work-study assignment in Italy that year to learn the ins and outs of the technique. Tamaro quickly found that the construction of slurry walls utilized a simple yet sound and remarkably effective technique. The process began with the excavation of a trench to bedrock in segments around the site of a proposed building. As each segment was excavated, the trench was filled with a thick bentonite slurry that both kept the trench open and prevented groundwater infiltration into it. Once the contractor had excavated the segment of trench to bedrock, a rebar cage was lowered into the slurry. Concrete was then placed from the bottom of the segment upward using a Tremie pipe. The denser concrete displaced the less-dense bentonite slurry, which could then be reused in subsequent segments of wall construction (Aronowitz 2002, PANYNJ 1983, Tamaro 2002).

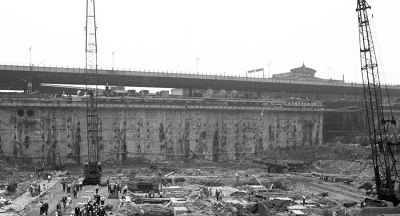

Design of the Twin Towers – formally named One and Two World Trade Center – progressed over the next several years as a series of political disputes and eminent domain lawsuits played out. Eventually, however, these hold-ups were resolved, and contractors broke ground for the skyscrapers in August 1966. The Port Authority used the critical path method to help expedite the work, marking one of the first uses of CPM on a large-scale civil engineering project. Accordingly, construction of the slurry wall began early in 1967, while demolition and utility relocation within the eight-block (16-acre) site of the World Trade Center was still underway. The Port Authority’s use of multiple equipment crews to construct the slurry wall also accelerated the project schedule. The immediate supervisors of the work were George Tamaro with the Port Authority and Arturo Ressi with Icanda, the Italian-Canadian contractor building the slurry wall (and now part of TREVIICOS). The 150-plus 3-foot-thick wall segments ultimately totaled nearly 3,400 feet in length around the site. As anticipated, conditions for the construction of the slurry wall were difficult and necessitated considerable design refinements in the field. Yet, amazingly, the wall was still completed by early 1968 (Aronowitz 2002, Dunlap 2013, Tamaro 2002).

Construction of the slurry wall progresses around the planned site of the Twin Towers, 1967.

Source: NYDN (2023)

The start of excavation within the footprint of the Twin Towers early in 1968 brought with it a fresh set of geotechnical challenges. Once again, the meticulous design work of the Port Authority geotech team ensured that these obstacles were overcome. The geotechs knew that their first challenge lay in the soils to be excavated. The organic marine clay underlying the debris fill at the site had a low undrained shear strength and was prone to relatively severe creep. Even worse, the heterogeneous glacial sand and silt underlying the clay drained so poorly that local contractors knew it to, sometimes, begin liquefying under mere foot traffic; they less than affectionately called the material “bulls’ liver” due to its visual and textural resemblance to raw meat. To best assess the engineering properties of these suboptimal soil layers, Port Authority geotechs took undisturbed (to the extent possible) samples from each one and assessed their strength using both UU triaxial tests (the marine clay layer) and CU triaxial tests with measurements of pore pressure (both layers). They then reduced the design parameters determined from these tests using an appropriate level of geotechnical conservatism (Aronowitz 2002).

Excavation progresses in the footprint of the Twin Towers, April 16, 1968.

Source: Rothman (2015)

As excavation proceeded, the slurry wall gradually became visible for the first time. The Port Authority geotech team was ready with an extensive reinforcement design to prevent excessive deflections of and moments within the wall. The reinforcement began with the wall panels themselves, in which contractors had installed 4 to 6 vertically-spaced rows of “trumpet” sleeve inserts – named for their shape – during wall construction. During excavation, as each row of sleeves was exposed, contractors inserted drills through the “trumpets” and advanced them 30 to 35 feet into the underlying Manhattan schist using steel pipe casing. They then threaded steel tieback anchors through the pipes and grouted them in place to securely brace the slurry wall against lateral earth pressures. Each tieback was tension-tested after grouting to make sure it could bear its required load capacity, which ranged around the site from 100 to 300 tons. Remarkably, of the 1,500 tiebacks installed for the project, only about 55 (4%) failed to pass tension testing and had to be bolstered with replacement anchors. Throughout excavation, the tension forces in the tiebacks were adjusted to minimize wall deflections and moments. The Port Authority geotechs also used a rigorous instrumentation program utilizing strain gauges, load cells, and inclinometers to monitor the performance of the wall and tiebacks predictions – a fine example of the observational method in action (Aronowitz 2002, Tamaro 2002).

The completed slurry wall for the Twin Towers with tiebacks clearly visible, summer 1968.

Source: NYDN (2023)

Still another difficulty that the geotech team handled adroitly during excavation at the Twin Towers site was the pair of steel-lined Port Authority Trans-Hudson (PATH) commuter rail tunnels which ran through the future basement of the Towers – several stories above their planned bottom of footing elevations. Port Authority geotechs were keenly aware that excavating near the tunnels without adequate dewatering would cause buoyancy to force them upward, while an overly aggressive program of dewatering would cause the tunnels to settle excessively. Neither extreme was acceptable for a line which carried 130,000 workers to and from Lower Manhattan each day. The geotech team thus began dewatering and excavating the soils surrounding the tunnels only after intensively instrumenting the interiors and exteriors of the tunnels using pore pressure cells and double-tube piezometers. During excavation, contractors constructed drilled shafts on each side of both tunnels and, once the tunnels were exposed, mounted steel trusses atop them. Then, as excavation continued, the contractors carefully underpinned the tunnels using steel straps and saddles connected to the overhead trusses. The geotech team also had inclinometers attached to select sections of the steel tunnel liner to monitor their positions. Service on the PATH trains was successfully continued without disruption throughout the entire process (Aronowitz 2002, PANYNJ 1983).

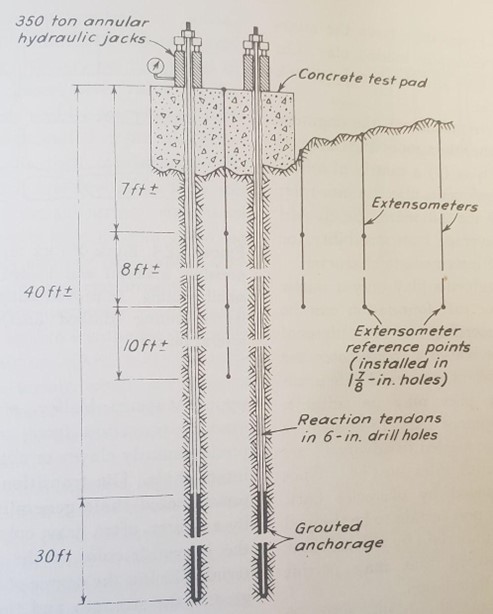

The Port Authority geotechs faced their next thorny issue once excavation had reached bedrock. There, they had to establish the quantity of explosive charges which could safely be used to blast rock inside the fragile slurry wall. To do so, the team cautiously ran a pilot program of blasting tests and used seismic assessments of the blast waves to refine their technique for site-wide rock removal. Once explosives contractors had reached the planned bottom of footing elevations, the geotechs used further seismic assessments to assess the strength of the Manhattan schist. However, the composition of the schist, which contains both zones of relatively weak mica and zones of far more durable quartz, made the Port Authority geotech team wary. They were understandably reluctant to trust conventional techniques for assessing bedrock, such as field seismic measurements or laboratory unconfined compression tests on rock samples, without ensuring that the latest geotech methods had been employed in constructing the foundations of the world’s tallest buildings. So, the team retained Professors Don Deere and A.J. Hendron of the University of Illinois at Urbana-Champaign, both pioneers in the nascent field of rock mechanics, as consultants on this phase of work. Under the professors’ guidance, the Port Authority engineers became some of the first geotechs in the world to use the Rock Quality Designation in practice, and also carried out a thorough program of field load testing. The field tests helped identify multiple zones of weak rock at the planned bottom of footing elevations; these values were subsequently revised once the weak rock had been removed. Field permeability testing was also conducted to design a drainage system for installation below the planned underground floors. The final bottom of footing elevations lay approximately 70 feet below the surrounding streets (Aronowitz 2002, PANYNJ 1983, Ressi 2011).

Diagram of the rock load test with instrumentation used to assess the Manhattan schist bedrock at the site of the Twin Towers.

Source: Peck et al. (1974).

Throughout the process of excavation, the Port Authority geotech team had been facing one final problem. Even once buried garbage and debris had been screened out from the excavated material, over 1,000,000 cubic yards of excavated soil and rock had to be removed from the site and disposed of, or reused, in a technically sound manner. The Port Authority chose to use the fill to construct new land, always at a premium in Manhattan, along the Hudson River across the West Side Highway (now West Street) from the Twin Towers. To accomplish this, the geotechs decided to seal the planned location of the site off from the river using cellular cofferdams. Contractors for the cofferdam began by dredging the soft marine clay at the river bottom to expose the underlying Manhattan schist, thus forming a series of connected trenches into which the bottoms of the cells would be driven. For each trench, the contractors used probing to verify that the clay had been dredged to bedrock and then immediately performed a controlled dump of sand until the bottom 10 feet of the trench had been backfilled with sand. Only then did the contractors drive steel sheet piling to form the cells of the cofferdam. Ultimately, placement of the screened fill produced 23 acres of new real estate, which the Port Authority gave to the City of New York. Eventually, the World Financial Center would be constructed on the filled site (Aronowitz 2002, PANYNJ 1983).

Back at the Twin Towers site, excavation continued briskly throughout the winter and spring of 1968. By early that summer, contractors had started excavating forms for the footings of the Towers out of the Manhattan schist, and construction of the buildings could begin. The Port Authority geotech team opted to design each footing using a grillage pattern consisting of two perpendicularly aligned, tightly welded layers of I-beams. The first grillage footing for One World Trade Center, nicknamed the North Tower, was placed in August 1968, and the first grillage for Two World Trade Center, aka the South Tower, followed suit in January 1969. The Port Authority geotechs then performed one closing task as structural steel construction for the Twin Towers progressed upward. As the girders of the underground floors began providing lateral support to the slurry wall, the wall’s tiebacks became potential liabilities, as a break in any one could impose differential stresses on the slurry wall. Thus, contractors followed close behind the steel workers as the Towers rose, de-tensioned each layer of tiebacks, and sealed the “trumpet” sleeves. The remaining years of the project marked a monumental achievement of structural, mechanical, and electrical engineering. Steel workers completed their work with impressive speed, topping out the North Tower in December 1970 and the South Tower in July 1971. Less than two years later, in the spring of 1973, officials celebrated the grand opening of the World Trade Center (Aronowitz 2002, PANYNJ 1983, Ressi 2011, Tamaro 2002, WTC 2020).

The first grillage footing is placed for the North Tower, August 6, 1968. Note its height relative to the workers placing it.

Source: Rothman (2015).

A smaller-scale failure would result in the flooding of the PATH tunnels – connected during construction of the Towers to a new terminal in the buildings’ underground floors – which, through connecting tunnels on the New Jersey side of the Hudson River, could then inundate the New York City subway system. A larger-scale slurry wall breach would cause the entire Hudson River to come pouring straight across Lower Manhattan. Either scenario would have been comparable, as a New York Times columnist noted, to Hurricane Sandy following the 9/11 attack by mere hours. A failure of the slurry wall that day would likely have raised the death toll from the attack by an order of magnitude....

Somehow, the slurry wall held.

The work of the Port Authority geotech team at the Twin Towers held up soundly for over three decades after the last grillage footing was placed and the final tieback sleeve was grouted. The detonation of a vehicular bomb inside the Towers’ underground parking garage on February 26, 1993, killed six victims and caused severe structural damage to the buildings’ underground floors but left the slurry wall unscathed. However, the far more lethal attacks of September 11, 2001, put the geotech team’s work to a truly dystopian test. The tragic collapse of the Twin Towers not only killed nearly 2,750 victims in and around the site but also created the potential for an even more mind-bendingly awful catastrophe. Arturo Ressi and George Tamaro, both world-renowned geotechs by 2001, recognized almost immediately that, with the Towers destroyed, their floors no longer provided methodical support to the slurry wall. Thus, with no lateral support from either tiebacks or the Twin Towers, the slurry wall was at imminent risk of collapse. A smaller-scale failure would result in the flooding of the PATH tunnels – connected during construction of the Towers to a new terminal in the buildings’ underground floors – which, through connecting tunnels on the New Jersey side of the Hudson River, could then inundate the New York City subway system. A larger-scale slurry wall breach would cause the entire Hudson River to come pouring straight across Lower Manhattan. Either scenario would have been comparable, as a New York Times columnist noted, to Hurricane Sandy following the 9/11 attack by mere hours. A failure of the slurry wall that day would likely have raised the death toll from the attack by an order of magnitude (Dunlap 2013, Mulroy 2023, Ressi 2011, Tamaro 2002).

Somehow, the slurry wall held. To ensure its continued integrity, a team of civil engineers joined first responders and clean-up crews at Ground Zero in the days following the 9/11 attack. The engineering team began assessing the condition of the slurry wall and utilities at the site as operations there slowly and solemnly shifted from search and rescue missions to recovery and cleanup efforts. The team, consulting with George Tamaro, determined that the weight of debris from the fallen towers was actually providing critical support to the slurry wall. The support could scarcely have been more critical, as portions of the wall had been forced inward over 4 feet following the collapse of the Twin Towers. The engineering team quickly began designing temporary safeguards to protect the wall while also permitting heavy (up to 1,000 tons) construction and demolition equipment to access the site. One early step involved plugging the PATH tunnels with concrete from their New Jersey portals, which significantly lowered the risk of flooding at the site. Others entailed constructing a dewatering system behind the slurry wall, installing inclinometers and monitoring wells around the site throughout cleanup to monitor any further wall movements, and building earthen embankments along key stretches of the wall to buttress it. Construction of these safeguards, along with demolition of the ruins of the Twin Towers, was paused whenever necessary to ensure the safe, dignified removal of human remains recovered at Ground Zero (Dunlap 2013, Ressi 2011, Tamaro 2002, Zehentner 2019).

Ground Zero in Lower Manhattan in the days following the 9/11 attack, September 2001. Source: Mulroy (2023).

Controlled demolition and removal of debris continued into 2002, by which time the engineering team’s efforts successfully stabilized the slurry wall in the near term. The team then turned its energies to designing permanent repairs for the wall. Early plans calling for reusing the original tieback tendons within the wall had to be revised after inspections revealed that the tiebacks had become severely corroded. Instead, new tiebacks capable of bearing 300 tons of tension were installed through the wall to bedrock. Meanwhile, a thick, steel-braced concrete liner was poured in front of most of the wall. It was at around this point, though, that a timely non-engineering consideration – specifically, the planning of the National September 11 Memorial and Memorial Museum – had a powerful and positive impact on the engineering team’s work. Daniel Libeskind, the head architect for the redevelopment of Ground Zero, visited the Twin Towers site in early 2002 and was instantly struck by the size and significance of the slurry wall. “I realized,” he later noted, “[that] this [wall was] not only about unimaginable destruction but [also] about the power of resurgence.” Libeskind concluded that featuring a portion of the original slurry wall within the Museum would be a fitting tribute to its role in preventing further devastation on 9/11. He and Arturo Ressi, who had readily bought into the idea, then persuaded both the engineering and Museum teams to support the plan (Dunlap 2008, Dunlap 2013, Tamaro 2002).

Mueser Rutledge Consulting Engineers, at which George Tamaro was a top-ranking engineer, spearheaded the effort to geotechnically preserve a section of the original slurry wall for display in the 9/11 Memorial Museum. The entire project team identified a 65-foot section of wall to be left exposed for visitor viewing in one of the main halls of the Museum. This section of the wall had already been reinforced with the new tiebacks, which would provide much of the needed support. The geotech team opted to supplement these tiebacks and compensate for the absence of the new concrete liner along the displayed section by having contractors construct a series of concrete counterfort piers behind it. For added safety, the geotechs also had the contractors spray the exposed section with a fresh layer of shotcrete. Now suitably buttressed, this section of the original slurry wall has formed an integral part of the Memorial Museum since its opening in 2014. It stands before the thousands of visitors who pass it each day as a silent yet eloquent tribute to the engineering ingenuity in the creation of the Twin Towers, to the utter horror of their destruction, and – in its own way – to resilience in the face of tragedy (Dunlap 2008, Dunlap 2013, Tamaro 2002).

Source: Graham-Felsen (2019).

Tribute in Light, an annual homage to the victims of the 9/11 attacks, as viewed from the National September 11 Memorial and Museum.

Source: NSMM (2021).

Works Cited

Aronowitz, A. 2002. “World Trade Center: Construction, destruction, and reconstruction.” 10th Spencer J. Buchanan Lecture, Texas A&M University, College Station, TX.

Dunlap, D. W. 2008. “For 9/11 wall, a little support and a permanent place.” The New York Times, April 28. Accessed September 10, 2023. https://www.nytimes.com/2008/04/28/nyregion/28wall.html

. 2013. “Looking to a wall that limited the devastation at the World Trade Center.” The New York Times, September 11. Accessed September 10, 2023. https://www.nytimes.com/2013/09/12/nyregion/looking-to-a-wall-that-limited-the-world-trade-centers-devastation.html

Graham-Felsen, J. 2019. “Public Program at the 9/11 Memorial Museum to Highlight Unique History of the Slurry Wall.” 9/11 Memorial & Museum. Accessed September 10, 2023. https://www.911memorial.org/connect/blog/public-program-911-memorial-museum-highlight-unique-history-slurry-wall

Mulroy, C. 2023. “How many people died in 9/11? Firefighters, passengers and more who died 22 years ago.” USA Today, September 8. Accessed September 11, 2023. https://www.usatoday.com/story/news/2023/09/08/how-many-people-died-911-attacks/70780975007/

NSMM (National September 11 Memorial & Museum). 2021. “Tribute in Light.” 9/11 Memorial & Museum. Accessed September 10, 2023. https://www.911memorial.org/visit/memorial/tribute-light

NYDN (New York Daily News). 2023. “The iconic Twin Towers through the years.” The New York Daily News, April 3. Accessed September 10, 2023. https://www.nydailynews.com/2023/04/03/the-iconic-twin-towers-through-the-years/

PANYNJ (Port Authority of New York and New Jersey). 1983. “Building the World Trade Center.” Accessed September 10, 2023. https://www.pbs.org/wgbh/americanexperience/features/newyork-construction/

Peck, R. B., W. E. Hanson, and T. H. Thornburn. 1974. Foundation Engineering, 2nd Ed. New York, NY, USA: John Wiley and Sons, Inc.

Ressi, A. 2011. “Transcript of audio recording of interview.” National September 11 Memorial & Museum: Oral Histories. Accessed September 10, 2023. https://www.911memorial.org/learn/resources/oral-histories

Rothman, L. 2015. “See 12 amazing photos of the World Trade Center under construction.” Time Magazine, December 23. Accessed September 10, 2023. https://time.com/4144821/world-trade-center-photos-construction/

Tamaro, G. J. 2002. “World Trade Center Bathtub: From Genesis to Armageddon.” The Bridge, 32 (1), 11-17.

Time. 1964. “Onward & Upward.” Time Magazine, January 24. Accessed September 10, 2023. https://time.com/vault/issue/1964-01-24/page/52/

WTC (World Trade Center). 2020. “‘World Trade Center Timeline of History.” Accessed September 10, 2023. https://www.wtc.com/about/history

Zehentner, S. 2019. Memory Foundation: The Story of the Slurry Wall: 9/11 Memorial and Museum. Documentary film. Accessed September 10, 2023. https://vimeo.com/361391698

Acknowledgments

Thomas Kennedy (Geopier: Davidson, NC) co-authored a previous version of this entry posted on an independent webpage in 2021.