Project Summary/Scope:

The Poudre Canyon Tunnel, located on State Highway 14, is a 75ft 2-lane rectangular tunnel. The tunnel was originally cut through a rock mass containing gneiss and other metamorphic rock. For some time prior, rockfalls had been an issue of the tunnel, which untensioned rock bolts were installed to mitigate. After failed attempts by the bolts to reduce the risk of rockfalls and with open fractures naturally occurring, polyurethane resin (PUR) was used to stabilize the rock mass.

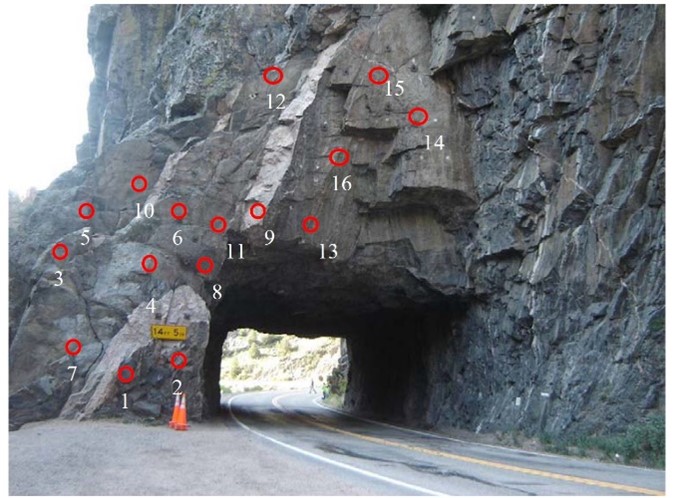

The project was to be completed in two weeks, with no work allowed from Friday to Sunday due to traffic constraints. It was estimated that 16 resin injections would be required to stabilize the fractured face.

The injection holes were created using a hand-held pneumatic rotary-percussive drill, which drilled 1.5in diameter holes 10 to 12ft deep. After drilling each hole, resin injecting immediately followed. A slender pipe was attached to the resin pump so that the resin could fill the back of the hole first and work its way to the face. Resin was pumped continuously until overflowing was observed. After that, the pumping was suspended for a minute to allow for the initial set, then pumping resumed so resin was pushed into new cracks to seal. The pumping pressure caused the resin to migrate laterally away from the hole, creating a large effective area of stabilization per installation hole (approximately 4 – 8ft radius). The rapid set of PUR allowed for injecting to take place without causing the displacement of loose rocks. The cleanup involved peeling or chipping away the resin that overflowed before the final set occurred. The injection holes were then covered with dark-colored grout, making them unnoticeable.

It was important this project was done efficiently because traffic had to be completely stopped during the drilling and resin injection. This was to minimize the risk of loose PUR landing on vehicles and damaging them. It was estimated that 850ft2 of tunnel area was treated from over 5000lb of PUR.

Complementary Technologies Used:

Alternate Technologies:

Untensioned rock bolts were installed in the past to reduce the risk of rockfalls.

Additional Photo:

Additional Photo or Drawing:

TBD

Performance Monitoring:

TBD

Cost Information:

The total cost of the project was approximately $42,000. This equates to about $8 per pound of resin installed.

Case History Author/Submitter:

Ben Arndt, Matthew DeMarco, & Richard Andrew

Yeh and Associates, Inc., 5700 East Evans Avenue, Denver, Colorado, 80222

Project Technical Paper:

Arndt, B., DeMarco, M., & Andrew, R. (2008). Polyurethane Resin (PUR) Injection for Rock Mass Stabilization (pp. 15-23, Rep. No. FHWA-CFL/TD-08-004). Lakewood, Colorado: Federal Highway Administration.

Date Case History Prepared:

January 2021