Rock Slope Stabilization Cost Information

Commentary

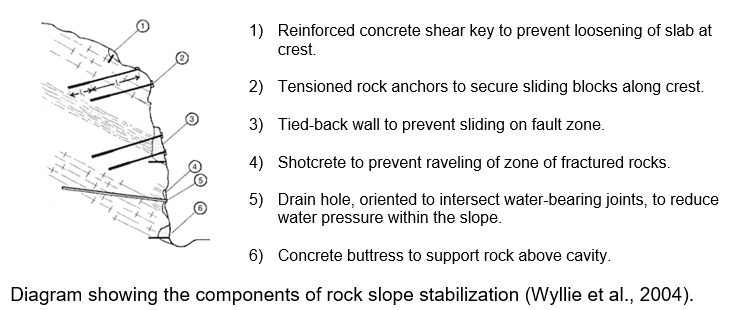

Rock slope stabilization is a generalized term for a wide range of devices or methods used to stabilize a rock face. Based on the specific technology being employed, the unit of measurement can change. Also, the unit of measurement can change based on the governing agency overseeing the project.

Rock Slope Stabilization Evaluation, Design and Construction Greater Boston, Massachusetts

Project Summary/Scope:

In 2014, a condominium was constructed in Boston, but found to be right in front of a rock slope that had some structural deficiencies.

Rock Slope Stabilization Fact Sheet

Basic Function:

Rock slope stabilization is used primarily as a preventative measure for both man-made and naturally occurring rock faces but is also implemented as a solution to rock slides, discontinuities in a rock face, or any detected instabilities that would present a danger to the integrity of the rock face.

Rock Slope Stabilization in Mythimna Castle

Project Summary/Scope:

Mythimna Castle, located on Lesvos Island in Greece, sits on a foundation of rock with multiple instabilities.

Rock Slope Stabilization Specifications

Summary of Example Specifications

Reference(s):

Ohio DOT (2018)

Oregon DOT (2020)

Rock blasting refers to the controlled use of explosives to produce a free surface in rock. The specifications for rock blasting use a method approach, focusing on blasting protocol rather than performance parameters. Both specifications are clear and thorough with what is expected of the Contractor. The specifications include required documentation, QC/QA test procedures, pre-blast surveys and safety plans, and data logging. The specifications mainly focus on methods to ensure safety since blasting has a high potential to cause harm to the workers or damage to the surrounding property. Payment for QC/QA and other monitoring methods is as a lump sum; payment for rock blasting varies depending on the agency. The Ohio DOT requires blasting to be paid by the square yard of the rock face while the Oregon DOT states that blasting is paid by the unit length which is calculated by dividing the area of the rock face by the blasting perimeter.

Reference(s):

WSDOT (2010)

Rock scaling is the removal of loose rock or soil from an existing rock slope that could cause a hazard. Specifications for rock scaling use a method approach to dictate the means of rock scaling preparation, execution, and cleanup. The Washington State Department of Transportation (WSDOT) provides some construction guidance for the Contractor to follow, mostly establishing requirements for documentation and safety. This is not a significant concern because scaling is a simple process that does not require heavy guidance. A note of concern is the WSDOT does not provide units for payment, which could be a point of dispute between the Contractor and Engineer.

Reference(s):

Oregon DOT (2020)

Slack (2018)

Specifications for rock bolt installation are a combination of the method and performance approaches. They guide the Contractor when selecting materials and equipment. Also, they explain the documentation required by the Contractor. The specifications use a performance approach to describe the performance and proof testing that must be conducted on each rock bolt, which is done by tensioning the bolts beyond the design load and recording the response as a way of quality assurance.

The specification written by Slack was for rock bolts bounded by resin or cement grout. It is clear and concise but lacks detail when describing the methods for construction compared to other rock slope stabilization techniques.

The specifications created by the Oregon DOT for rock bolts and rock slope stabilization are more comprehensive, going into detail about recommended construction practices. The Oregon DOT lumped rock bolts bound by cement grout with rock slope meshes into one section.

Reference(s):

LBNL (2008)

NYSDOT (2020)

Specifications for tiebacks are addressed with a method and performance approach. The Lawrence Berkeley National Laboratory (LBNL) and the New York State Department of Transportation (NYSDOT) provide detailed QC/QA procedures for contractors to follow during construction. The specifications are very stringent with the materials and methods for tieback installations. Specifications also require the Contractor to perform quality assurance tests on the tiebacks per the Post-Tensioning Institute (details provided in QC/QA Section). The amount of detail is necessary so tiebacks are installed in a way to minimize the chance of slope failure.

The LBNL Specification is very detailed for its limited use, as it is a specification created only for geotechnical projects for the University of California. Its contents mostly consist of the QC/QA standards that must be met without addressing safety procedures, means of payment, or other sections that comprise a completed specification.

The NYSDOT Specification for tiebacks is much more complete. It includes guidance for tieback installation, so the tendons do not shear, corrode, or fail in any other way. The guidance given is clear and detailed, so there is little room for uncertainty from the Contractor. This specification provides the basis for payment, where the payment is per tieback installed.

Reference(s):

NYSDOT (2020)

Oregon DOT (2020)

SPEC MIX Inc (2019)

Shotcrete is mortar being projected at a high velocity onto a surface by a pressurized hose with applications going beyond just slope stabilization. For the three example specifications, the context for the New York DOT specification is for structural concrete repair, the context for the Oregon DOT specification is for slope stabilization, and the specification by SPEC MIX is for general shotcrete application. These specifications can be classified as a method approach to describe each phase of shotcrete installation, from surface preparation to curing, while still giving the Contractor flexibility.

The New York DOT provides a clear and descriptive specification for shotcrete application. The procedure for QC/QA is included in this specification, but unlike other rock slope stabilization technologies, the tests are conducted by a third party off-site. It should be noted, shotcrete in this document is for structural repair, but the same regulations would apply if for rock slope stabilization.

The Oregon DOT specification encapsulates each phase of the construction process. It addresses documentation, materials and equipment requirements, QC/QA sampling, nozzleman requirements, site preparation, shotcrete application, and payment. Unlike the specification provided by the New York DOT, this specification addresses the importance of adding weep holes to the shotcrete face for slope stabilization.

The specification provided by SPEC MIX Inc is specifically for incorporating the shotcrete design mixture that they manufacture. Therefore, the specification is detailed when addressing the application, but the sections regarding the QC/QA and responsibilities of the Contractor are vague. The detail in the shotcrete application section without being for a specific scenario makes the document well suited for educational purposes.

Shotcrete

<p>Reference(s):</p> <p>SPEC MIX, Inc</p> <p>Shotcrete is applied to an exposed rock face to help protect against weathering and cracking over time. This solution is not supposed to be used as a safeguard against falling rocks, but rather, protect against the future degradation of the rock slope in general, and increase the lifespan of all of the other methods of stabilization that have been implemented. When shotcrete is installed, holes are needed to be drilled for drainage, as the water pressure can build up over time if an outlet for it is not provided.

Tieback Walls

Reference(s):

Sabatini et al. (1999)

Weatherby, D. E. (1988)

New York DOT (2020)

Water Pressure Monitoring

<p>Reference(s):</p> <p>Schuster & Turner (1996)</p> <p>Wyllie & Mah (2009)</p> <p> </p> <p><strong>Method Summary</strong></p> <p>Installing a drainage system is one method of improving the stability of a rock slope. To measure the effectiveness of drainage, piezometers are used to measure the water pressure within the rock slope. Piezometers are buried in the slope to measure the water pressure in the immediate vicinity of the device.