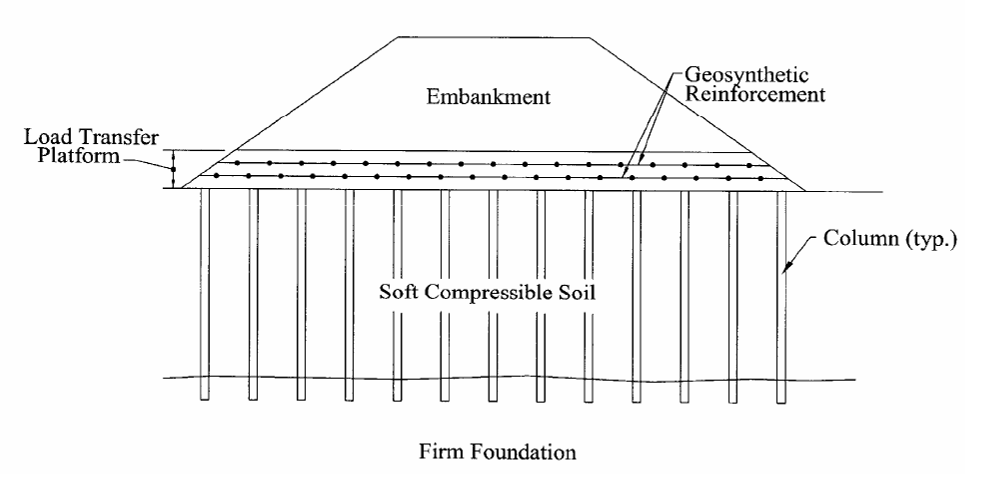

Column Supported Embankment with Geosynthetic Reinforcement (Figure from Elias et al. (2006))

Basic Function:

Column-Supported Embankments (CSE) enable construction of embankments over unstable soils by transferring the load to a stiffer underlying stratum.

Advantages:

- Accelerates construction compared to conventional methods

- Reduces total and differential settlement

- Protects adjacent facilities from distress

- Can be used with a wide variety of columns to accommodate different site conditions

General Description:

Column-supported embankments are used when the unimproved soil is too soft or compressible to support the embankment. The columns transfer the embankment load to a firm stratum below the soft layer. Columns are generally end-bearing in most CSE applications, but floating columns can be used depending on the site geology, the project requirements, and the type of column used. When high-capacity columns with wide spacings are used, geosynthetic reinforcement and/or enlarged pile caps are typically used at the interface between the top of the columns and the embankment to enable more efficient load transfer to the columns.

Geologic Applicability:

- Typically used on soft compressible clay, peats, and organic soils where settlement and global stability are concerns

- Most cost effective when the compressible material thickness ranges from 15 to 70 feet (4.6 to 21.3 meters)

- Soft soil underlain by stiffer soil or bedrock

Construction Methods:

Columns of strong material are placed in the soft ground to provide the necessary support by transferring the embankment load to a firm stratum. Numerous column types may be used for this technology with or without pile caps, including continuous flight auger piles, drilled displacement piles, driven piles, vibro-concrete columns, and aggregate columns. A load transfer platform (LTP), also known as a load transfer mat (LTM) or bridging layer, is usually constructed immediately above the columns to help transfer the load from the embankment to the columns. The LTP generally consists of compacted select fill and may include geosynthetic reinforcement. The type of select fill and geosynthetic reinforcement used in the LTP depend on the design procedure employed. Load transfer platforms are used more often when the spacing between columns is relatively large (i.e., greater than 5 feet), which requires higher load carrying capacity from the columns. Aggregate columns, because of their lower vertical load capacity, are often spaced close enough together that a LTP is not required.

SHRP2 Applications:

- New Embankment and Roadway Construction

- Roadway and Embankment Widening

Example Successful Applications:

- Rancocas Creek Railroad Bridge – NJ

- I-95/Route 1 Interchange – Alexandria, VA

- Minnesota TH241 Widening – St. Michael, MN

Complementary Technologies:

Many different column technologies can be used with CSEs. Some applications may use lightweight fill in combination with column-supported embankments

Alternate Technologies:

Technologies for similar applications include preloading with or without PVDs, lightweight fill, excavation and replacement, staged construction, and geosynthetic reinforcement embankments.

Potential Disadvantages:

CSEs can incur a higher cost than technologies that require more time before the embankment can be put into service. CSEs also suffer from a lack of standard design procedures and lack of knowledge about design procedures and construction techniques.

Key References for this technology:

Filz, G. M., Sloan, J. A., McGuire, M. P., Smith, M., Collin, J. 2019. “Settlement and Vertical Load Transfer in Column-Supported Embankments.” J. Geotech. Geoenviron. Eng.,145(10): 04019083. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002130.

Schaefer, V.R., Berg, R.R., Collin, J.G., Christopher, B.R., DiMaggio, J.E., Filz, G.M., Bruce, D.A., and Ayala, D. 2017. “Ground modification methods reference manual – Volume II.” Geotechnical Engineering Circular No. 13 (GEC 13). Washington, D.C: Federal Highway Administration (FHWA).

GeogridBridge 3.0 User and Theory manuals that are accessible from within this document